10 Leading Manufacturers of Feed Pelletizing Equipment in Europe

Looking for Zhengzhou Meijin premium feed equipment that redefines standard quality of pet? To the top 10 European manufacturers! Because of their dedication to safe, exceptional service quality and never standing still in the face of most efficient methods and results possible on a consistent basis they have established themselves as some standout names for the animal feed industry.

Benefits:

The cow feed pellet machine are much easier to use for processing feed. This makes it far easier to handle, transport store and utilises the feed. Traditional feed processing is usually labor-intensive and inconsistent. This new equipment enhances production process accuracy and reliability.

Development:

Recipe for Success: 3 Special Ingredients The success of all manufacturing companies clearly benefits from innovation, but this is where European manufacturers particularly shine. They are at the forefront of creating state-of-the-art technology which not only aids efficiency but also serves to meet ever-changing consumer demands.

Safety:

These manufacturers are continuing to put safety at the forefront of their devices and each device is designed with maximum consideration for meeting international standards. Each of these companies provides safety and health compliant products to ensure the protection from injuries for their employees, as well they build in features that protect the operators when using equipment.

Usage:

Pelletizing equipment is easy to use. The equipment can vary in sizes, shapes and complexities a common feature is that European manufacturers always make them easy to use ensuring anyone at even modest level of experience with operating such machinery should be able to handle it.

How to Use?

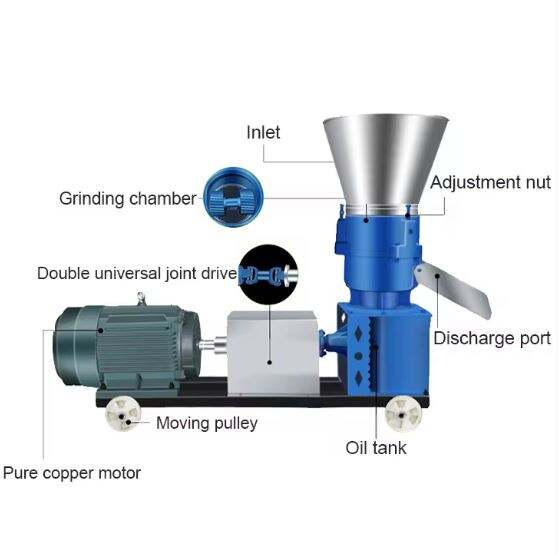

We need to know what we are looking for in the end use of a feed and make sure our knowledge base is correct with how each piece of equipment affects that specific type-feed. The machine is loaded with the feed, desired settings are dialed in and off it goes. After processing, the feed pellet mill were collected and bagged in usable conditions.

Service:

To ensure that all manufacturing operations run smoothly, post sales support is very important. Since the manufacturers understand that uninterrupted operation is of higher priority, they provide services such as maintenance and reparation aids, replacement parts for heavily-used components or information about new hardware versions available to upgrade systems with their latest knowledge.

Quality:

Quality is the essential foundation of reliable manufacturing practices, and European manufacturers are firmly rooted in their commitment to delivering high-quality pellets that exceed industry benchmarks for satisfied customers.

Application:

The manufacturers construct equipment that satisfies a various animal feed market demands with their solutions being capable of transformation raw materials such as grasses, straw, hay, soybeans and corn husks into feed pellet making machine of varying sizes. Their main use is in the production of pet feeds, bedding and litter for pets like cats as well livestock such pigs which this showcases just how efficient these machines are at servicing a variety industries.